Hot melt adhesive systems are the lifeblood of many packaging, converting, woodworking, and product-assembly operations. At the centre of every system is a heated hose, responsible for carrying molten adhesive from the melter to the applicator at precisely controlled temperatures.

The photo above shows a cutaway of a Nordson style hot melt hose after years of use. It’s an excellent example of what happens inside when conditions aren’t ideal and why hoses eventually clog, char, and fail. Heated hoses are used on pretty much every type of hot melt glue tank – whether it be a Robatech, Nordson, Valco, Meler, ITW Dynatec, Graco or a UES AG

How a Hot Melt Hose Works

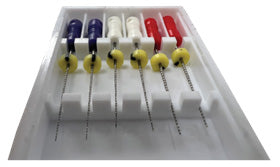

A typical heated hose is made of several layers, all visible in the cutaway image:

-

Hose Core (Centre Channel)

This is the internal tube where molten adhesive flows. It must stay at a stable temperature—hot enough to keep the glue molten, but not so hot that it begins to degrade. -

Heating Elements & Wiring

Surrounding the core are electrical heating wires and sensors (the coloured copper wires shown). They maintain the set temperature throughout the hose’s length. -

Thermal Insulation Layer

The thick white fibrous layer insulates the hose so it maintains temperature and reduces energy use. -

Outer Protective Jacket

Finally, the black woven mesh and rubber coating protect the hose from abrasion, bending, and daily production wear.

Why Hot Melt Hoses Get Blocked

Over time, the hot conditions inside the hose can cause adhesive breakdown. Here’s how the blockages form:

-

Heat-Sensitive or Fast-Degrading Glues Break Down Quickly

Some EVA, PSA, and metallocene adhesives are more prone to thermal degradation. If they sit too long at temperature—especially in hoses—they oxidize and carbonize. This creates:

• Char flakes

• Gelled adhesive

• Thick tar-like residues

These deposits stick to the core and gradually reduce flow. -

Excessively High Operating Temperatures

Running hotter than necessary accelerates oxidation. Even a 10–15°C increase can dramatically reduce adhesive life and start forming carbon deposits. High temperature these days is considered anything over 130C -

Hoses Left On for Long Periods (Overnights, Weekends)

When equipment is left heated without glue movement, the adhesive sits still in the hose. Without flow, it literally cooks. The result is exactly what’s visible in the image: a hose interior coated with char, restricting the bore and eventually blocking it completely. -

Contaminated or Poor-Quality Adhesives

Fillers, dust, or incompatible formulations can make degradation faster or cause physical blockages.

Signs Your Hose Is Starting to Block Watch for:

- Reduced output at the applicator

- Pump cycling more frequently

- Increased pressure readings

- Stringing or sputtering glue beads

- Temperature fluctuations (when sensors get coated with char) Early detection can save a hose.

The Anatomy of a Failure

The hose in the photo shows:

- Severe interior carbonization where the adhesive has baked onto the core

- Exposed, discoloured wiring from prolonged heating

- Scorched insulation fibres - a sign of running too hot for too long

- Outer jacket wear, usually from abrasion or repeated flexing

This level of damage means the hose was beyond recovery, but it tells a story many production facilities know all too well.

How to Prevent Hose Blockages

Here are practical steps to extend hose life:

✔ Run at the lowest temperature that still ensures good flow Don’t rely on “one temperature fits all” settings.

✔ Turn hoses off during long stops Or use a standby mode if your melter supports it.

✔ Use adhesives with good thermal stability Especially for operations that involve long idle periods.

✔ Schedule periodic purging Some facilities purge with a stable polyolefin adhesive to clean out degrading EVA.

✔ Keep an eye on maintenance logs Most hoses that fail early were consistently run too hot.

Conclusion

A hot melt hose is more than a heated tube, it’s a carefully engineered system. When temperatures stay controlled and adhesive is kept moving, hoses can last years. But as the image shows, once glue begins to degrade and char inside, blockages become inevitable.